- HOME

- Silica Glass

Silica Glass

Silica glass is a special kind of glass that is composed almost entirely of SiO2. Compared to other types of glass, which contain other elements, silica glass has very low levels of metallic impurity, ranging from 10 ppm at the most to less than 10 ppb for high-purity grades. It is this extremely high level of purity that provides silica glass with its superb features that cannot be found in other types of glass.

Features of Silica Glass

Silica Glass Material

Our company manufactures products out of silica glass materials manufactured by Tosoh SGM, one of our affiliated companies. We select the material that best matches the quality level and specifications required by our customers. This website introduces our silica glass materials and their various characteristics.

For detailed information about these materials, please visit the TOSOH CORPORATION website.

Lineup of Silica Glass Material

| Category | Process | Grade | Features |

|---|---|---|---|

| Fused Silica Glass | Oxy-hydrogen flame fusion | N | Semiconductor standard grade, Less bubbles |

| NP | High-purity grade of N | ||

| S | High-purity grade with good light transmission | ||

| OP-1 | Semiconductor standard grade opaque | ||

| OP-3 | Semiconductor high-purity grade opaque | ||

| OP-3HD | OP-3 grade with enhanced surface smoothness | ||

| Electrically fused | HR | Semiconductor standard grade, High heat resistance | |

| HRP | High-purity grade of HR | ||

| Synthetic Silica Glass | Oxy-hydrogen flame fusion (Verneuil type process) |

ES | Standard optical grade for optics |

| ESL-1 | Standard optical grade with 1D striae free | ||

| ESL-1000 | Enhanced excimer durability for ESL-1 | ||

| ESL-2 | Good homogeneity with 3D striae free | ||

| ESL-2000 | Enhanced excimer durability for ESL-2 | ||

| Oxy-hydrogen flame fusion (VAD process) |

ED-H | Good homogeneity with 3D striae free | |

| ED-C | Very low OH content (OH content < 1ppm) |

Purity

Fused silica glass is manufactured from high-purity silica powder, and synthetic silica glass is manufactured from high-purity SiCl4. Impurity levels for fused silica glass are measured in the ppm region and for synthetic silica glass in the ppb region.

◎Impurity Level of Major Silica Glass Material

| Variation | Grade | Al | Ca | Cu | Fe | Na | K | Li | Mg | OH | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Fused | Transparent | N | 8 | 0.6 | <0.01 | 0.2 | 0.6 | 0.1 | <0.01 | 0.04 | 200 |

| NP | 7 | 0.5 | <0.01 | 0.1 | 0.1 | 0.03 | <0.01 | 0.02 | 200 | ||

| S | 0.7 | <0.01 | <0.01 | 0.05 | 0.3 | <0.01 | <0.01 | <0.01 | 160 | ||

| HR | 15 | 0.6 | 0.02 | 0.2 | 0.8 | 0.6 | 0.5 | 0.1 | 10 | ||

| HRP | 15 | 0.6 | 0.01 | 0.2 | 0.2 | 0.6 | 0.2 | 0.1 | 10 | ||

| Opaque | OP-1 | 8 | 0.7 | <0.01 | 0.2 | 0.5 | 0.3 | 0.07 | 0.04 | 160 | |

| OP-3 | 7 | 0.6 | <0.01 | 0.07 | 0.06 | 0.03 | 0.07 | 0.02 | 160 | ||

| OP-3HD | 7 | 0.6 | <0.01 | 0.07 | 0.06 | 0.03 | 0.07 | 0.02 | 160 | ||

| Synthetic | Transparent | ES*1 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | 1000 |

| ED-C | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <1 | ||

| ED-H | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <100 | ||

(Typical values Not guaranteed)

*1: Impurity level of ESL-1, ESL-2, ESL-1000 and ESL-2000 is the same as ES.

Chemical Characteristic

The extreme chemical resistance of silica glass makes it highly suitable as a distillation container for various solvents and acid solutions, and as a dissolution and washing container for various kinds of substances. Attention must be paid when using it for long periods of time, however, because solutions and environments containing hydrofluoric acid, phosphoric acid, alkali, or alkali metal compounds may cause etching and/or surface devitrification.

◎Chemical Reactivity with Acid/Alkaline Solutions

| Solution | Condition | Weight Loss(m2) | |||

|---|---|---|---|---|---|

| Concentration(%) | Temperature(℃) | Time(Hr) | |||

| Alkali | NH4OH | 10 | 20 | 100 | 0.19 |

| NaOH | 1 | 20 | 100 | 0.31 | |

| 10 | 20 | 100 | 0.095 | ||

| 5 | 100 | 10 | 15 | ||

| 8 | 100 | 10 | 12.1 | ||

| KOH | 1 | 20 | 100 | 0.19 | |

| 30 | 100 | 10 | 0.27 | ||

| 10 | 10 | 100 | 11.3 | ||

| Na2CO3 | 5 | 20 | 100 | 0.015 | |

| 10 | 100 | 10 | 3.7 | ||

| Acid | H2SO4 | 98 | 205 | 24 | 0.06 |

| 98 | 20 | 240 | 0.016 | ||

| HNO3 | 65 | 115 | 24 | 0.11 | |

| 65 | 20 | 240 | 0.06 | ||

| HCl | 37 | 66 | 24 | 0.14 | |

| 37 | 20 | 240 | 0.18 | ||

(Typical values Not guaranteed)

◎Chemical Reactivity with Other Materials

| Metal | Al, Mg | Rapid reaction at 700-800℃ |

| Au, Ag, Pt | No reaction | |

| Zn, Sn, Pb | No reaction | |

| Si | Slight reaction when fused | |

| Ge | No reaction at 900℃ | |

| Mo, W | No reaction | |

| Oxide | Al2O3 | Gradual reaction over 900℃ |

| CaO | Reaction over 900℃ | |

| CuO | Reaction over 800℃ | |

| Fe2O3 | Reaction over 900℃ | |

| PbO | Intense reaction when fused | |

| MgO | Slight reaction at 900℃ | |

| ZnO | Reaction over 420℃ | |

| Gas | CO, SO2 | No reaction |

| N2, O2 | No reaction | |

| Cl2 | No reaction | |

| F2 | No reaction with dried gases under 300℃ | |

| H2 | No reaction | |

| HCl | No reaction | |

| Salt | BaCl2 | Reaction when fused |

| BaSO4 | Reaction over 700℃ | |

| CaCl2 | Slight reaction when fused at 800℃ | |

| KCl | Acceleration of devitrification at high temp. | |

| KF | Intense reaction when fused | |

| NaCl | Reaction visually recognized over 800℃ | |

| Na2SO4 | No reaction |

Optical Characteristics

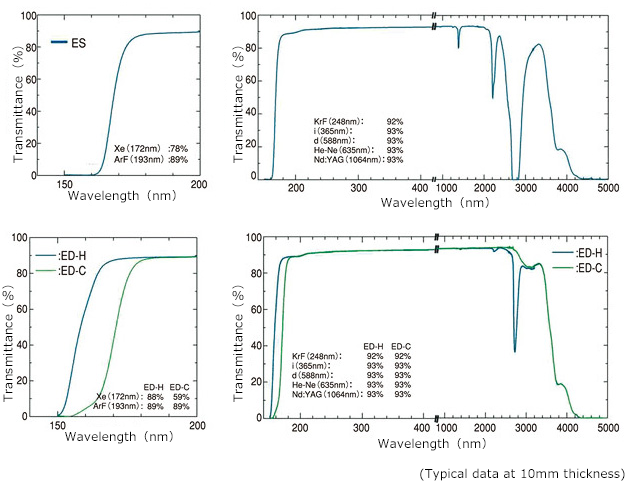

We have lineups of ES series and ED series optical materials. Both are synthetic silica glass materials made from high-purity SiCl4. They have almost no impurities, bubbles, or foreign materials, and have excellent optical transparency in a wide range of wavelengths across the spectrum from vacuum ultraviolet to infrared.

◎Optical Properties of Major Optical Grade Silica Glass Material

| Grade | Striae*1 | Homogeneity*2 Δn(x10-6)within clear aperture |

Strain (nm/cm) |

Excimer Durability | Applicable Wavelength*3 (nm) |

|---|---|---|---|---|---|

| ES | N/A | N/A | 1~20 | N/A | 180~2,100 |

| ESL-1 | 1D | 3~10(CA:φ300mm) | 1~10 | N/A | 180~2,100 |

| ESL-1000 | 1D | 3~10(CA:φ300mm) | 1~10 | Negotiable*4 | 180~2,100 |

| ESL-2 | 3D | <10(CA:φ300mm) | 1~10 | N/A | 180~2,100 |

| ESL-2000 | 3D | <10(CA:φ300mm) | 1~10 | Negotiable*4 | 180~2,100 |

| ED-H | 3D | 5~10(CA:φ180mm) | 1~10 | N/A | 170~2,600 |

| ED-C | N/A | N/A | 1~10 | N/A | 180~3,400 |

(Typical values Not guaranteed)

*1: Striae specification is defined as following. 1D: 1 direction free 3D: 3 direction free

*2: Homogeneity means refractive index homogeneity and is expressed as Δn(PV) within effective area.

For questions regarding materials with greater homogeneity, non-standard sizes and guaranteed values

please contact us separately.

*3: Applicable wavelength is defined as the wavelength range where external transmittance is more than 80%/cm.

*4: Excimer durability is specified with Tosoh SGM’s KrF and ArF excimer laser damage tests.

◎Spectral Transmission of Major Optical Grade Silica Glass Material

Mechanical, Thermal and Electrical Characteristics

Silica glass has unique properties that cannot be found in other materials. For example, silica glass’s rigidity, pulling strength, bending strength, etc. increase with a rise in temperature, culminating at around 800°C to 1,000°C before suddenly decreasing at temperatures that exceed those levels.

◎Physical Properties of Major Silica Glass Material

| Item | Unit | ES*1 | ED-C | ED-H | N, NP | HR, HRP | S | OP-1,3 | OP-3HD | |

|---|---|---|---|---|---|---|---|---|---|---|

| Mechanical | Density | cm3 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.02 | 2.1 |

| Young’s modulus | GPa | 74 | 74 | 74 | 74 | 74 | 74 | — | — | |

| Shear modulus | GPa | 31 | 31 | 31 | 31 | 31 | 31 | — | — | |

| Poisson’s ratio | 0.18 | 0.18 | 0.18 | 0.17 | 0.17 | 0.17 | — | — | ||

| Bending strength*2 | MPa | 94.3 | 94.3 | 94.3 | 94.3 | 94.3 | 94.3 | 60 | 67 | |

| Compressive strength | MPa | 1,128 | 1,128 | 1,128 | 1,128 | 1,128 | 1,128 | — | — | |

| Tensile strength*2 | MPa | 49 | 49 | 49 | 49 | 49 | 49 | — | — | |

| Torsion strength | MPa | 29 | 29 | 29 | 29 | 29 | 29 | — | — | |

| Vickers hardness | MPa | 8,900 | 8,900 | 8,900 | 8,900 | 8,900 | 8,900 | 8,900 | 8,900 | |

| Thermal | Strain point (η=1014.5) |

℃ | 970 | 970 | 1,060 | 1,070 | 1,120 | 1,060 | 1,050 | 1,050 |

| Annealing point (η=1013) |

℃ | 1,080 | 1,080 | 1,170 | 1,180 | 1,220 | 1,165 | 1,170 | 1,170 | |

| Softening point (η=107.6)*3 |

℃ | (1,720) | (1,720) | (1,720) | (1,720) | (1,720) | (1,720) | (1,720) | (1,720) | |

| Coefficient of thermal expansion 30~600℃ |

x10-7/ ℃ | 4.7 | 4.7 | 4.7 | 5.9 | 5.9 | 5.9 | 6.9 | 6.9 | |

| Specific heat 20℃ |

J / kg・K | 749 | 749 | 749 | 749 | 749 | 749 | 749 | 749 | |

| Thermal diffusivity 20℃ |

x10-7m2/ s | 8.5 | 8.5 | 8.5 | 8.3 | 8.3 | 8.3 | 8.4 | 8.5 | |

| Thermal conductivity 20℃ |

W / mK | 1.38 | 1.38 | 1.38 | 1.38 | 1.38 | 1.38 | 1.24 | 1.33 | |

| Viscosity (logη)1200℃ |

Poise | 10.60 | 10.60 | 11.37 | 11.72 | 12.18 | 12.10 | 11.72 | 11.72 | |

| Electrical | Dielectric constant 500MHz |

3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.7 | 3.8 | |

| Dielectric loss 500MHz |

x10-3 | <1 | <1 | <1 | <1 | <1 | <1 | <1 | <1 | |

| Resistivity | Ω | 5×1015 | 8×1015 | 8×1015 | 3×1015 | 8×1015 | 4×1015 | — | — | |

| Volume resistivity | Ω・cm | 1x1017 | 1x1017 | 1x1017 | 5x1016 | 1x1017 | 7x1016 | — | — | |

(Typical values Not guaranteed)

*1: Properties of ESL-1, ESL-2, ESL-1000 and ESL-2000 are the same as ES.

*2: Bending and Tensile strengths are affected by surface conditions.

*3: Estimate from extrapolation.

NOTE: Unless otherwise stated, all values represent typical data at 25℃